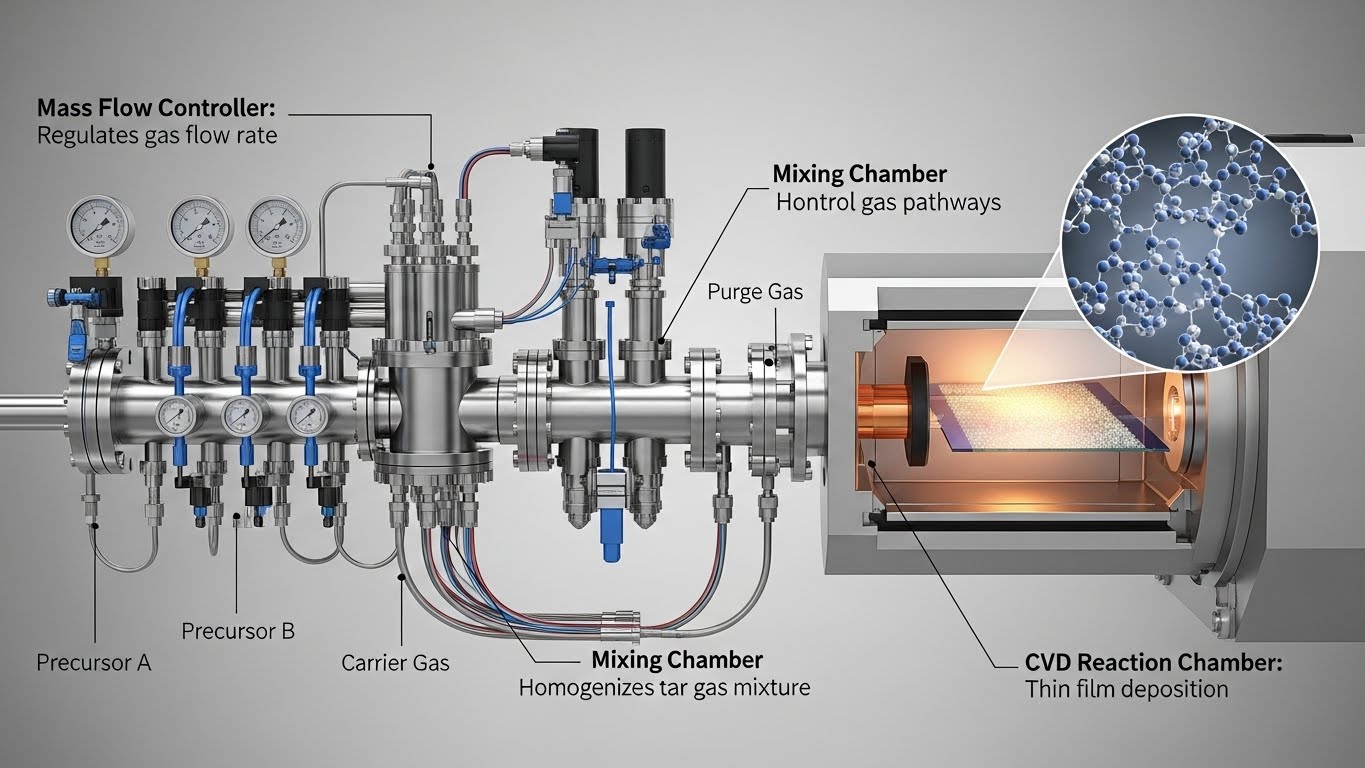

The gas manifold of CVD systems plays a central role in modern material processing and semiconductor manufacturing. Chemical Vapor Deposition, commonly known as CVD, relies on the controlled delivery of reactive gases to deposit thin films on substrates. The gas manifold acts as the distribution hub that manages multiple gas sources, ensuring accurate flow, pressure stability, and safe handling. Without a well-designed gas manifold, achieving consistent film quality and process reliability would be extremely challenging.

Understanding the Function of a Gas Manifold

At its core, the gas manifold of CVD systems is responsible for mixing, regulating, and delivering gases into the reaction chamber. These gases may include precursors, carrier gases, and dopants, each requiring precise control. The manifold ensures that the correct gas reaches the chamber at the right time and concentration. This precision directly impacts film thickness, uniformity, and chemical composition, making the gas manifold a foundational component of the entire CVD process.

Key Components Within the Gas Manifold

A typical gas manifold of CVD systems includes mass flow controllers, valves, pressure regulators, filters, and safety interlocks. Mass flow controllers regulate the exact amount of gas entering the system, while valves control timing and sequencing. Pressure regulators maintain stable operating conditions, and filters remove contaminants that could compromise film quality. Together, these components form a tightly integrated system designed for accuracy, repeatability, and safety in high-precision environments.

Importance of Precision and Control

Precision is essential in CVD processes because even minor variations in gas flow can lead to defects or inconsistencies in deposited films. The gas manifold of CVD systems allows engineers to finely tune gas delivery parameters, ensuring uniform deposition across the substrate. This level of control is especially critical in advanced applications such as semiconductor wafers, optical coatings, and nanomaterial fabrication, where tolerances are extremely small.

Safety Considerations in Gas Manifold Design

Many gases used in CVD processes are hazardous, flammable, or toxic, making safety a top priority. The gas manifold of CVD systems is designed with multiple safety mechanisms, including leak detection, automatic shutoff valves, and pressure relief systems. These features protect both equipment and personnel while ensuring compliance with industrial safety standards. A properly maintained gas manifold reduces operational risks and supports stable long-term performance.

Role in Process Consistency and Scalability

Consistency is a major requirement in industrial manufacturing, and the gas manifold of CVD systems plays a direct role in achieving it. By delivering gases in a repeatable and controlled manner, the manifold ensures that each deposition cycle produces similar results. This reliability also makes it easier to scale processes from laboratory research to full-scale production, supporting innovation while maintaining quality.

Maintenance and Performance Optimization

Regular maintenance of the gas manifold is essential to preserve performance and accuracy. Over time, contaminants, wear, or calibration drift can affect gas delivery. Proper inspection, cleaning, and calibration help maintain optimal operation. A well-maintained gas manifold of CVD systems contributes to higher yield, reduced downtime, and longer equipment lifespan, making it a critical focus area for process engineers.

Conclusion

The gas manifold of CVD systems is a vital component that enables precise, safe, and reliable thin film deposition. By controlling gas flow, pressure, and composition, it directly influences process quality and consistency. Its design integrates precision engineering with safety considerations, making it indispensable in both research and industrial environments. Understanding the function and importance of the gas manifold highlights its role as the backbone of successful CVD operations and advanced material manufacturing.